Miners Carts for the Stars

"... How could we say no!"

Back before the global pandemic, when bands were touring and venues were packed with excited fans eager to experience the thrill of live music, we were privileged to have had a small part in a major tour.

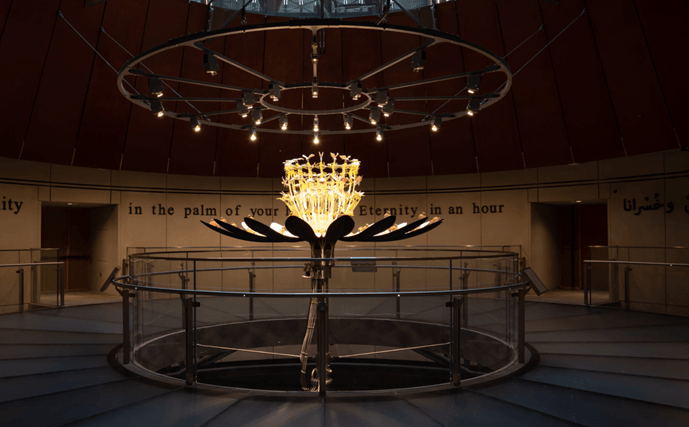

As is usually the case with live events, the timescales were challenging – four weeks from initial phone call to delivering the kit. We were called on a Friday and asked to help deliver a solution to transport band members from the mainstage, through a tunnel under the passerelle to its centre. The band would then raise from the centre of the passerelle among the crowd. How could we say no!

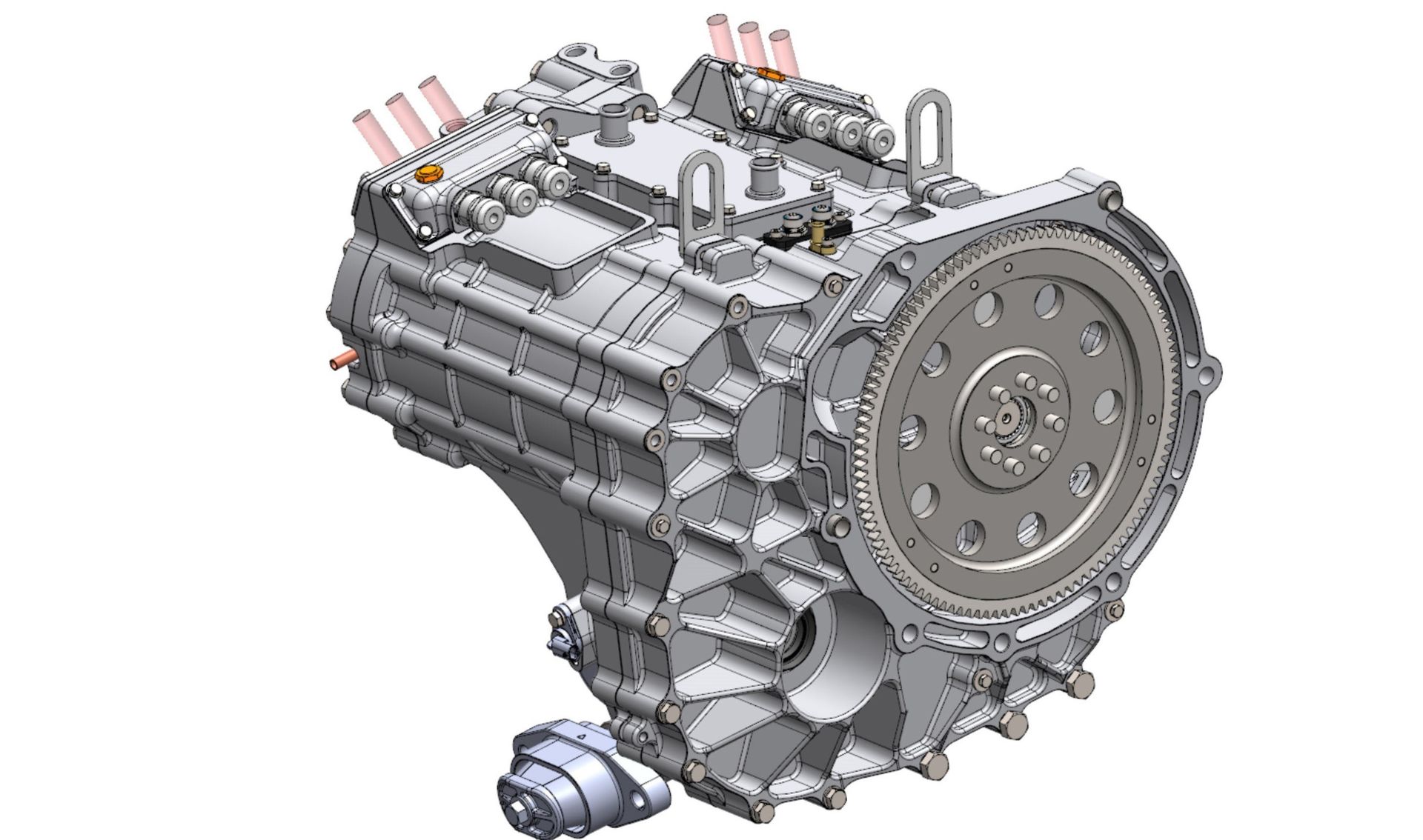

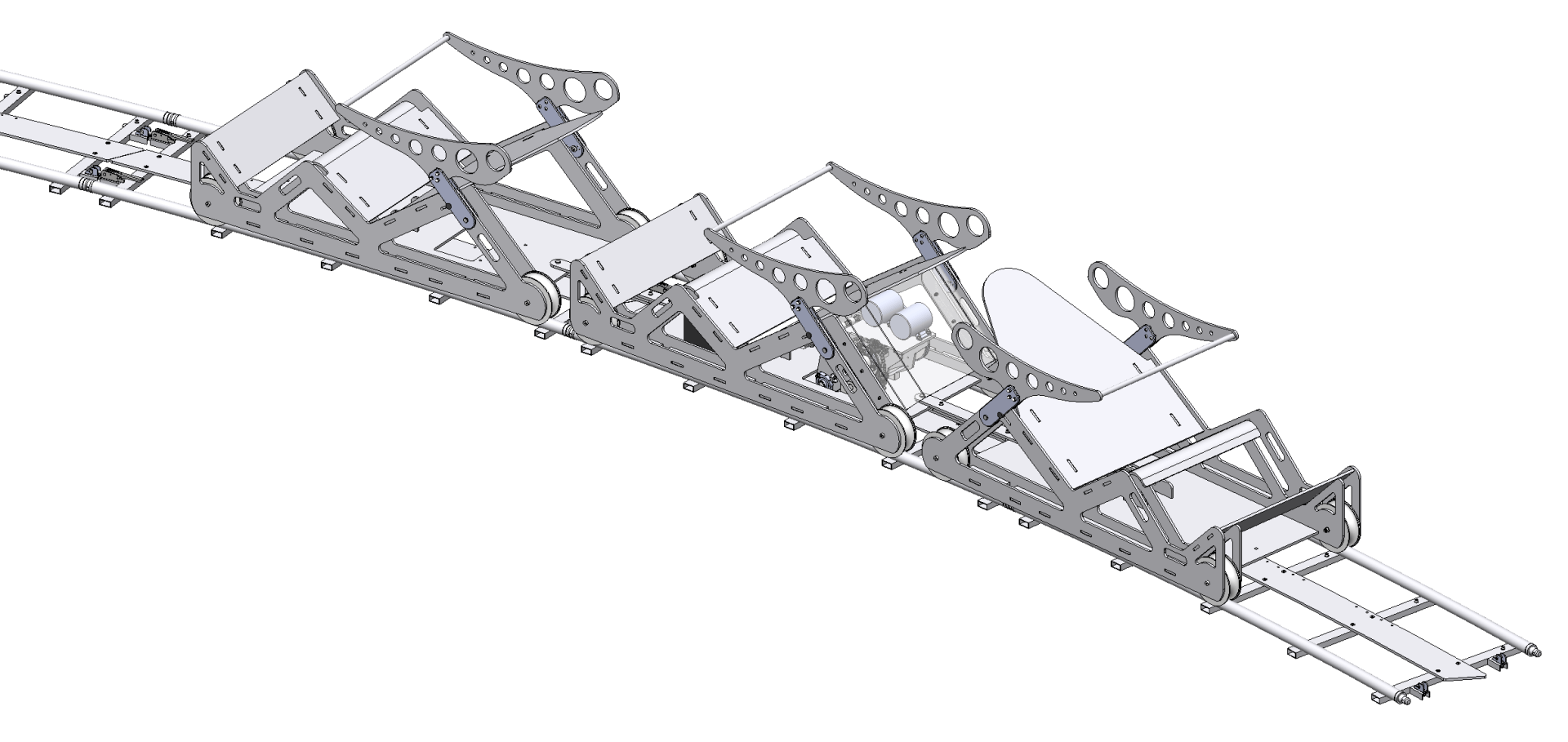

We started with a meeting with the client where we quickly brainstormed several concepts before arriving at a concept that would work and could be delivered in the timescales required. A week of detailed design followed with a keen eye on function and manufacturability. The structure of the Carts was chosen to be made from profiled Aluminium plate, with tabs and slots for easy fabrication. One of the most challenging areas was sourcing a drive motor and gearbox to suit our requirements. Everything we looked at had a lead-time of 6 weeks or more. We ended up designing the drive system before we knew how we would power it. We eventually solved the drive motor issue – a cheap 12V tuk-tuk motor. Due to the unknown quality of the motor, rather than spending time sourcing alternatives or testing we simply used two per drive for redundancy.

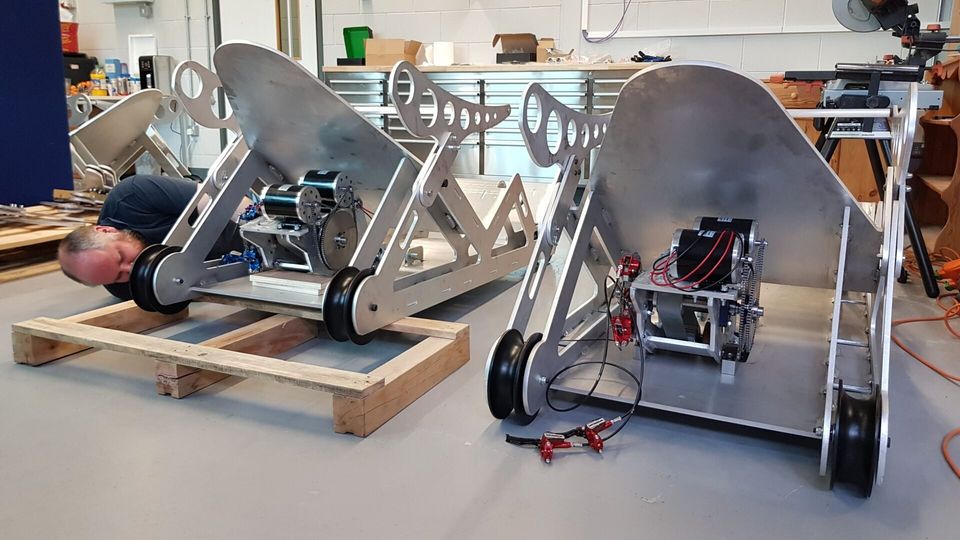

Using our network of local machine shops and fabricators we were able to get all the components manufactured and delivered to our workshop in two weeks. Our suppliers certainly pulled out all the stops for which we were very grateful.

The Carts were assembled and bench tested in our workshop before being delivered to our clients for testing on the track. Testing complete, the carts were loaded onto trucks the very same day for delivery to the bands rehearsal venue.

Words don’t really do the project justice – the videos are much more fun. Please enjoy.