Rotating Machinery – only a little different

"...hold infinity in the palm of your hand"

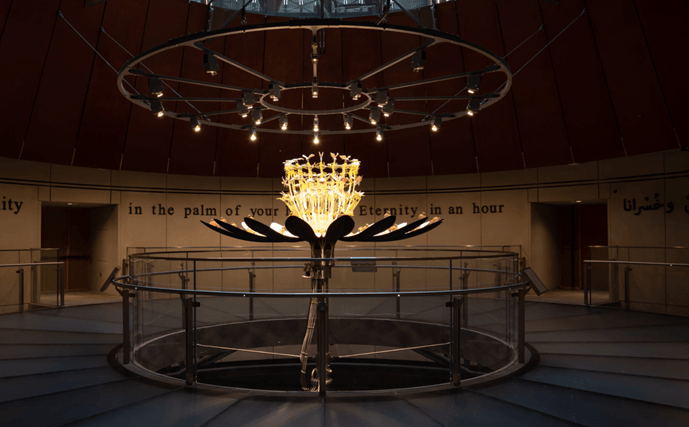

Photo credit: Dubai Expo 2020

World Expos are international celebrations exploring a theme relevant to topical issues. The first Expo was held in 1851 and they've been held regularly ever since. The Dubai Expo 2020 is the latest event in this long-held tradition. Rearranged due to the Covid-19 pandemic, the event’s grand opening on 1st October 2021 was watched by millions across the globe and over 9 million guests are expected to visit in person before the closing ceremony on 31st March 2022. The key theme for this year’s Expo is sustainability, and as we type this, exhibitors from around the world are presenting novel and fascinating solutions to problems faced by humanity in the 21st Century.

The organisers of Expo 2020 sought a similarly bold and creative piece of artwork which would sit in "Terra - The Sustainability Pavilion", one of three pavilions at the event. Commissioned by the Expo 2020 organisation, British artist Mat Collishaw created "Equinox".

Brier Solution’s involvement in the creation of this centrepiece started back in 2019 when we were approached by The White Wall Company. The White Wall Company are art fabricators who work with some of the world’s most renowned contemporary artists and gallery spaces creating show-stopping sculptures and exhibitions.

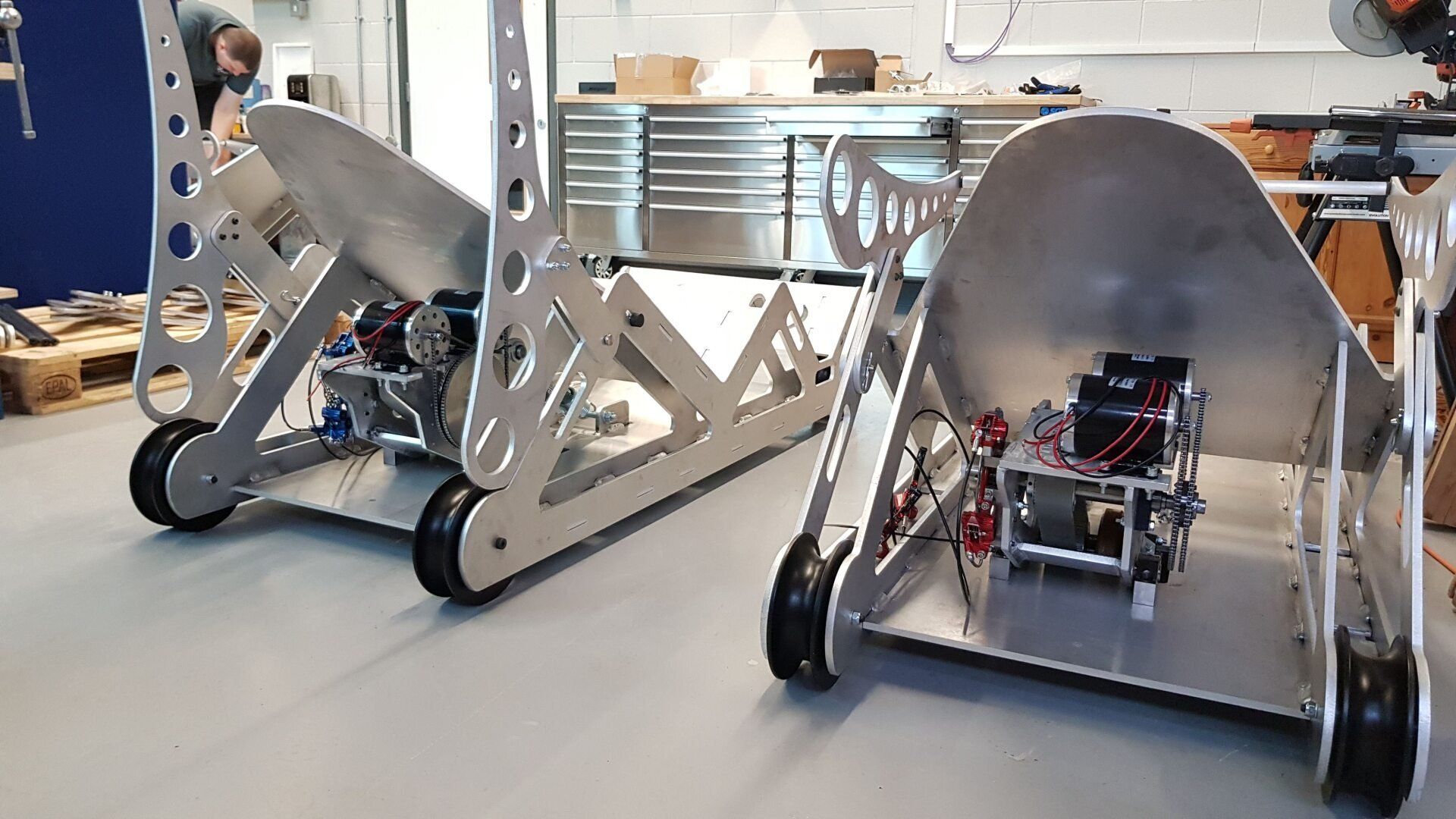

The sculpture, a Giant Lotus Flower Zoetrope, needed to consist of a flower that would raise and lower 1m, spin at 60 RPM and have 18 petals that would open and close, changing the diameter from 2m to 3.2m. The stem, supporting the flower, needed to be as slender as possible and facilitate the raising and lowering. All this needed to happen in a tight envelope and be as elegant and refined as possible.

It was a prerequisite that to realise the potential of this artwork, the enabling engineering must be invisible and seamless. We were cognisant of this key requirement as we moved through our engineering design process.

We undertook an optioneering stage to identify the best concept to take forward to the detailed design stage. We investigated the use of various electrically powered options, such as lead screws and linear chains for the raise and lower function, and an electric motor for spinning the flower. We also knew we needed an inconspicuous mechanism to provide the opening and closing of the petals. With an estimate of the mass of each petal we were able to calculate the forces in the mechanism required to hold them while spinning at 60 RPM, which equated to a 20 tonne force at the actuators.

As a result we concluded that the loads being experienced by the system would make these options too bulky for the overall aesthetic required.

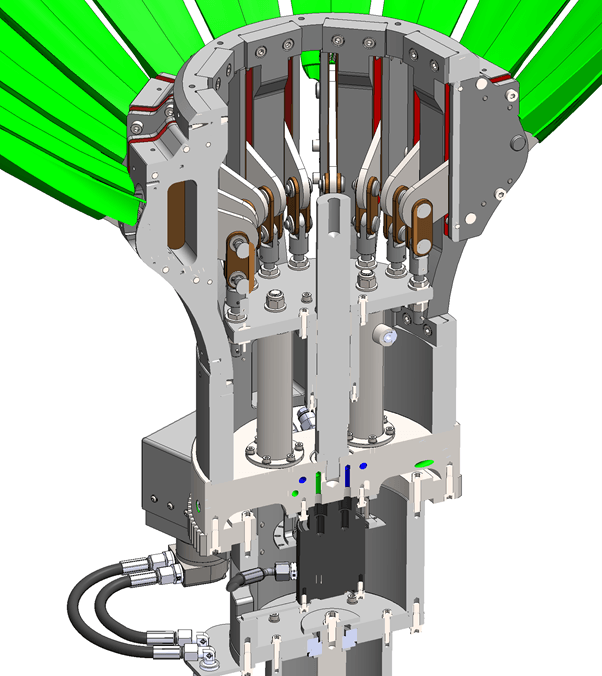

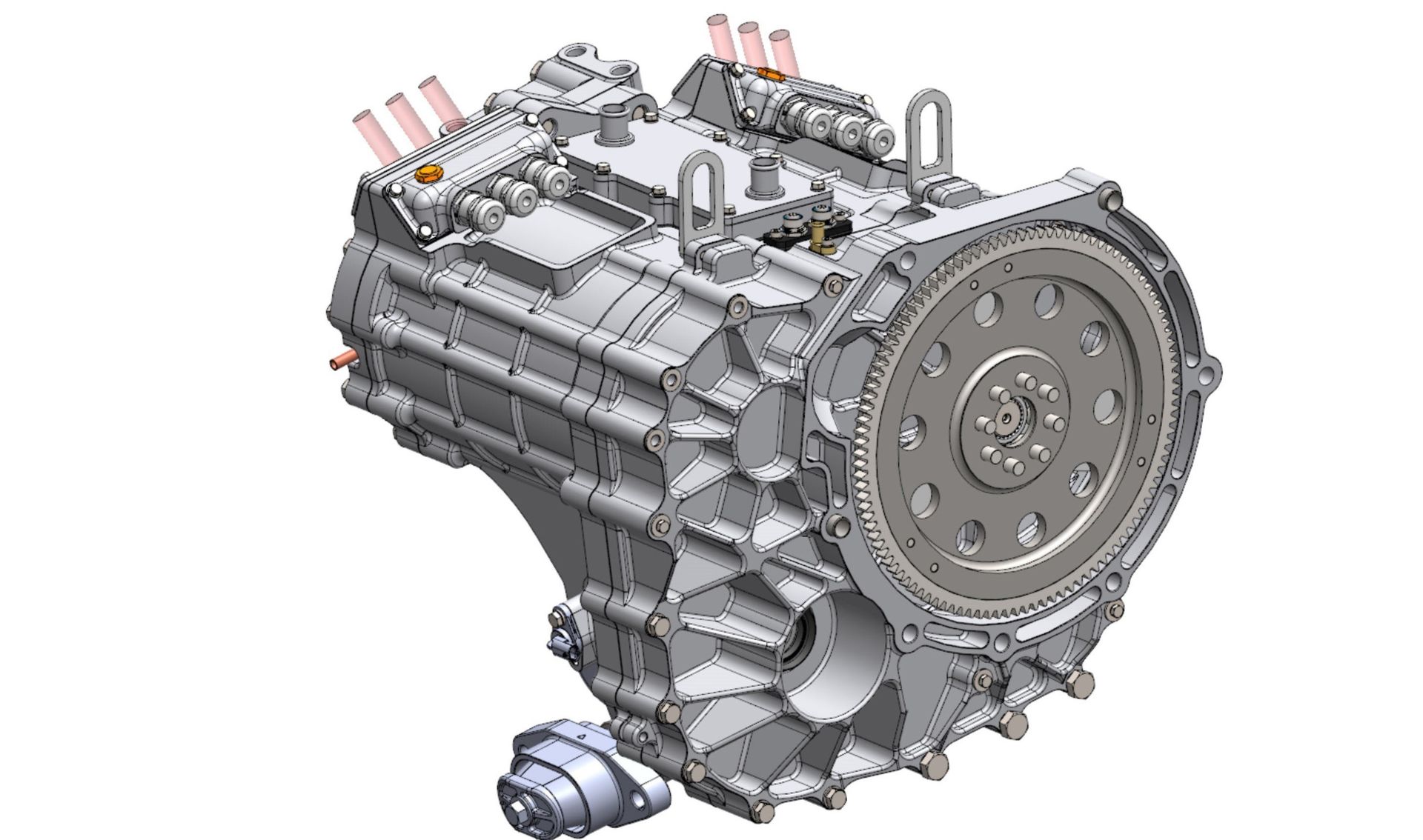

The solution was found using hydraulics; a single hydraulic cylinder mounted in the stem for the raise/lower operation, 3 mini cylinders mounted directly to a bespoke manifold in the top section to actuate the opening/closing mechanism and a single hydraulic motor to drive a small slew ring for the rotation. Aware of the importance of engineering invisibility, one of the main benefits of using a Hydraulic system was the power density of the actuators. This meant we could keep the design as slender as possible and store the HPU in a remote plant room away from the sculpture to reduce noise levels when in use.

As well as selecting the most appropriate actuation for the piece we also had to ensure that bearings and bushes were correctly selected to provide reliable, squeak-free and wobble-free operation over the required lifetime. And to conclude our work we carried out hand calculations and FEA on the components to ensure they satisfied the fatigue and fault load cases.

Brier Solutions are proud to have been trusted to deliver this truly unique project and we thoroughly enjoyed working with all involved. We hope you will agree that the finished piece is spectacular and worthy of its place as the centrepiece of the Terra Pavilion.

Please contact Brier on

0114 4055 995 or

enquiries@briersolutions.co.uk to discuss your mechanical design requirements.